| Availability: | |

|---|---|

| Quantity: | |

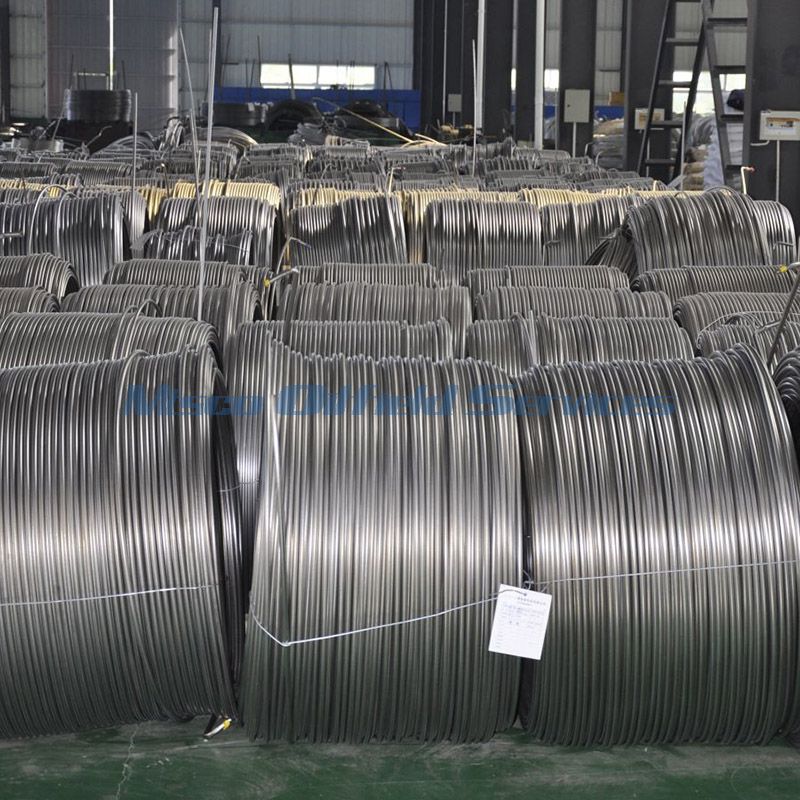

ASTM A213 Nickel Alloy 625/UNS N06625 Welded Coiled Tubing for Oil Industry

MTSCO has been supplying coiled tubing for the international geothermal, heat exchanger, shipbuilding, oil and gas industries for more than 10 years. In recent years, we have made breakthroughs in the fields of coiled tubing, downhole control lines and chemical injection control lines. We mainly produces welded/seamless coiled tubing, single/multi-core control line, capillary tube and other coiled tubing. The main materials are stainless steel, duplex steel and nickel alloy. The length can be more than 33000 fts/coil. The size, length, pressure and packaging method can be customized to ensure equipment quality and reduce maintenance costs.

The benefits of coiled tubing are as follows:

Reduced installation labor costs: Installing continuous lengths of pipe with coiled tubing proves more time-efficient and reliable compared to connecting multiple shorter lengths of pipe. This not only streamlines the installation process but also contributes to cost savings in labor.

chemical property:

| Grade | C max | Si max | Mn max | P max | S max | Cr | Ni | Mo | Ti | N max | Cu max | Nb | Al max | Co max | Zr | Fe max | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

| Alloy 718/N07718 | 0 | 0 | 0 | 0 | 0 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | 0.65-1.15 | 0 | 0 | 4.75-5.5 | 0.2-0.8 | 1 | - | - | - | - |

| Alloy 800/N08800 | 0 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 800H/N08810 | 0.05-0.10 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 825/N08825 | 0 | 1 | 1 | - | 0 | 19.5-23.5 | 38-46 | 2.5-3.5 | 0.6-1.2 | - | 1.5-3 | - | 0 | - | - | ≥22 | - | - |

Physical Property:

| Grade | Physical Property | |||

| Y.S | T.S | EL. | HB | |

| Alloy 600/N06600 | 205-345 | 550-690 | 35-55 | ≤185 |

| Alloy 601/N06601 | 240-300 | 600-650 | 30-35 | ≤220 |

| Alloy 625/N06625 | ≥345 | ≥760 | ≥30 | ≤220 |

| Alloy 718/N07718 | ≥550 | ≥965 | ≥30 | ≤363 |

| Alloy 800/N08800 | ≥210 | ≥500 | ≥35 | - |

| Alloy 800H/N08810 | ≥180 | ≥450 | ≥35 | - |

| Alloy 825/N08825 | ≥220 | ≥550 | ≥30 | ≤200 |

| Package | Level wound, the smaller dimensions level wound on wooden or plastic spools per coil, the packed by plywood case 1. Plywood case 2. Wooden spools 3. Woven bags | |

MTSCO specializes in the production and supply of coiled tubing, hydraulic control tubing, hydraulic control lines, tubing encapsulated cables, chemical injection lines, and multi-core tube bundles. The products are widely used in petroleum, chemical, natural gas, shipbuilding, food, environmental protection, and other industries, especially from standard well-workover and velocity/production strings for logging, drilling, and special application strings with factory-installed wire-line, capillary tubes to integral tools. Our continuous coiled tubing in lengths is suitable for the most challenging downhole environments.

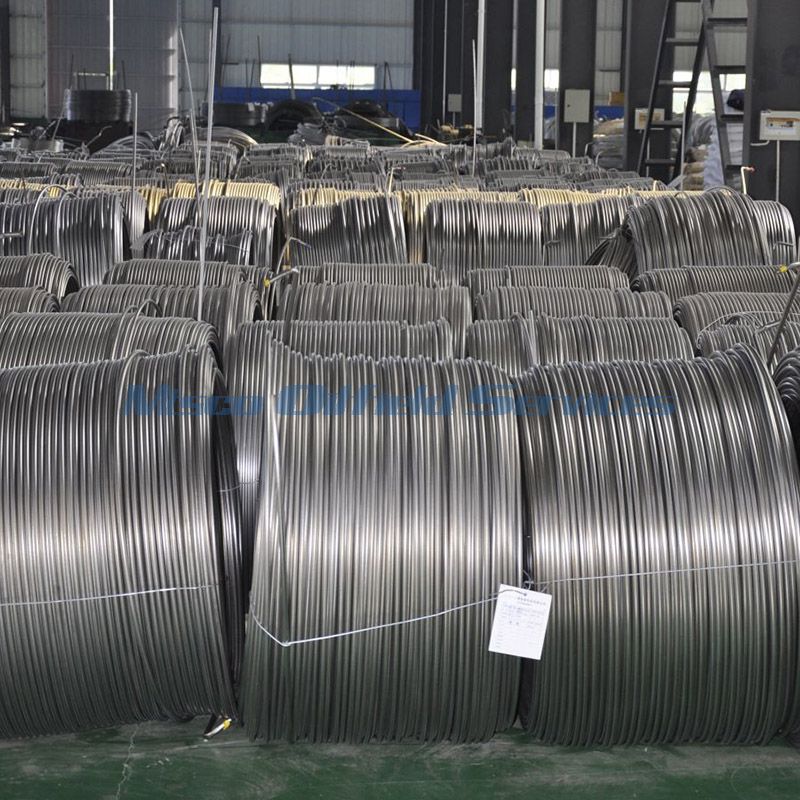

ASTM A213 Nickel Alloy 625/UNS N06625 Welded Coiled Tubing for Oil Industry

MTSCO has been supplying coiled tubing for the international geothermal, heat exchanger, shipbuilding, oil and gas industries for more than 10 years. In recent years, we have made breakthroughs in the fields of coiled tubing, downhole control lines and chemical injection control lines. We mainly produces welded/seamless coiled tubing, single/multi-core control line, capillary tube and other coiled tubing. The main materials are stainless steel, duplex steel and nickel alloy. The length can be more than 33000 fts/coil. The size, length, pressure and packaging method can be customized to ensure equipment quality and reduce maintenance costs.

The benefits of coiled tubing are as follows:

Reduced installation labor costs: Installing continuous lengths of pipe with coiled tubing proves more time-efficient and reliable compared to connecting multiple shorter lengths of pipe. This not only streamlines the installation process but also contributes to cost savings in labor.

chemical property:

| Grade | C max | Si max | Mn max | P max | S max | Cr | Ni | Mo | Ti | N max | Cu max | Nb | Al max | Co max | Zr | Fe max | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

| Alloy 718/N07718 | 0 | 0 | 0 | 0 | 0 | 17.0-21.0 | 50.0-55.0 | 2.8-3.3 | 0.65-1.15 | 0 | 0 | 4.75-5.5 | 0.2-0.8 | 1 | - | - | - | - |

| Alloy 800/N08800 | 0 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 800H/N08810 | 0.05-0.10 | 1 | 2 | - | 0 | 19-23 | 30-35 | - | 0.15-0.60 | - | 1 | - | 0.15-0.60 | - | - | ≥39.5 | - | - |

| Alloy 825/N08825 | 0 | 1 | 1 | - | 0 | 19.5-23.5 | 38-46 | 2.5-3.5 | 0.6-1.2 | - | 1.5-3 | - | 0 | - | - | ≥22 | - | - |

Physical Property:

| Grade | Physical Property | |||

| Y.S | T.S | EL. | HB | |

| Alloy 600/N06600 | 205-345 | 550-690 | 35-55 | ≤185 |

| Alloy 601/N06601 | 240-300 | 600-650 | 30-35 | ≤220 |

| Alloy 625/N06625 | ≥345 | ≥760 | ≥30 | ≤220 |

| Alloy 718/N07718 | ≥550 | ≥965 | ≥30 | ≤363 |

| Alloy 800/N08800 | ≥210 | ≥500 | ≥35 | - |

| Alloy 800H/N08810 | ≥180 | ≥450 | ≥35 | - |

| Alloy 825/N08825 | ≥220 | ≥550 | ≥30 | ≤200 |

| Package | Level wound, the smaller dimensions level wound on wooden or plastic spools per coil, the packed by plywood case 1. Plywood case 2. Wooden spools 3. Woven bags | |

MTSCO specializes in the production and supply of coiled tubing, hydraulic control tubing, hydraulic control lines, tubing encapsulated cables, chemical injection lines, and multi-core tube bundles. The products are widely used in petroleum, chemical, natural gas, shipbuilding, food, environmental protection, and other industries, especially from standard well-workover and velocity/production strings for logging, drilling, and special application strings with factory-installed wire-line, capillary tubes to integral tools. Our continuous coiled tubing in lengths is suitable for the most challenging downhole environments.