| Availability: | |

|---|---|

| Quantity: | |

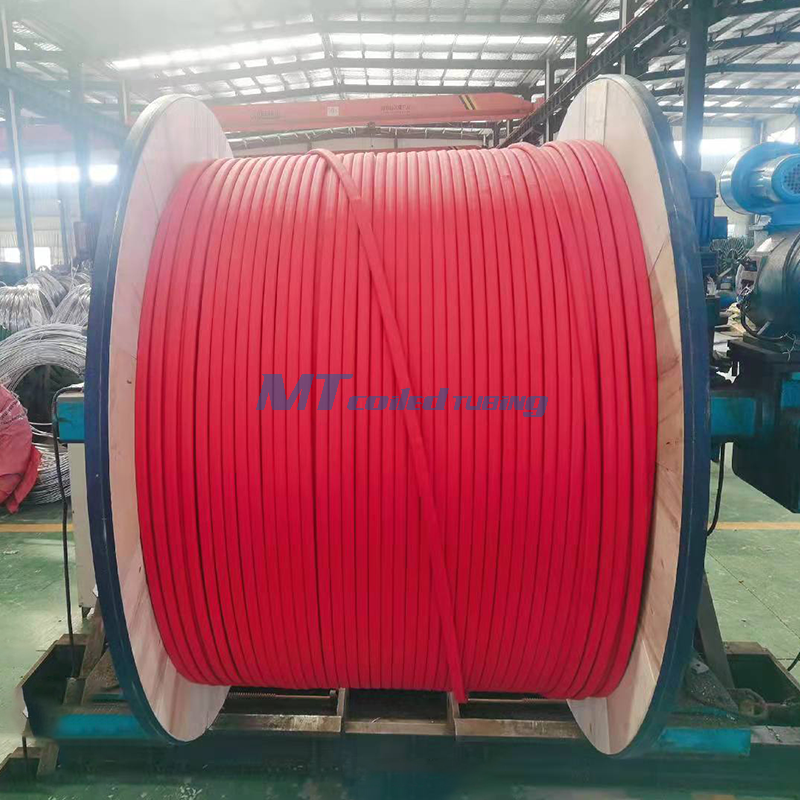

Alloy 825/UNS N08825 ASTM Chemical Injection Line with Iron Reel Package

Grade | Alloy 825/N08825, Alloy 625 /N06625, Alloy 400/ N04400, 2205, 2507, TP316/L, TP304/L, etc |

Type | Welded |

Hole count | Single/Multi Core |

Outer Diameter | 1/4'', 3/8'', 1/2'' |

Wall Thickness | 0.035'', 0.049'', 0.065'' |

Length | According to customers' needs, up to 10000m |

Standard | ASTM A269/A213/A789/B704/B163,etc. |

Certificate | ISO/CCS/DNV/BV/ABS, etc. |

Inspection | NDT; Hydrostatic test |

Package | Wooden or iron reel |

Application of Control Line:

1. Heat Exchanger

2 . Control line in oil and gas well

3 . Instrument tubing

4 . Chemical injection tubing line

5 . Pre-insulated tubing

6 . Electric heating or steam heating tubing line

7 . Hater tubing line

What is Chemical Injection Line ?

Chemical Injection lines are very important material in the chemical injection system.

Chemical Injection System provides operators with precise wellbore chemical management, which is designed to optimize flow assurance and production performance and lower high cost intervention.

Chemical injection line tube usually is a coiled tubing. The coiled tubing is made of stainless steel, duplex stainless steel or nickle alloy. The coiled tubing mostly is welded & redrawn tube or seamless cold drawn tube.

|  |

Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

Payment | T/T, LC or as negotiation | |

Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

Package | Wooden or iron reel or as per customer’s requirement | |

Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

Quality | Test | NDT(Ultrasonic test, Eddy Current test) |

Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | ||

Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | ||

Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

An increasing number of projects in the oil service industry require the use of continuous lengths of nickel alloy chemical injection lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex chemical injection lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

Alloy 825/UNS N08825 ASTM Chemical Injection Line with Iron Reel Package

Grade | Alloy 825/N08825, Alloy 625 /N06625, Alloy 400/ N04400, 2205, 2507, TP316/L, TP304/L, etc |

Type | Welded |

Hole count | Single/Multi Core |

Outer Diameter | 1/4'', 3/8'', 1/2'' |

Wall Thickness | 0.035'', 0.049'', 0.065'' |

Length | According to customers' needs, up to 10000m |

Standard | ASTM A269/A213/A789/B704/B163,etc. |

Certificate | ISO/CCS/DNV/BV/ABS, etc. |

Inspection | NDT; Hydrostatic test |

Package | Wooden or iron reel |

Application of Control Line:

1. Heat Exchanger

2 . Control line in oil and gas well

3 . Instrument tubing

4 . Chemical injection tubing line

5 . Pre-insulated tubing

6 . Electric heating or steam heating tubing line

7 . Hater tubing line

What is Chemical Injection Line ?

Chemical Injection lines are very important material in the chemical injection system.

Chemical Injection System provides operators with precise wellbore chemical management, which is designed to optimize flow assurance and production performance and lower high cost intervention.

Chemical injection line tube usually is a coiled tubing. The coiled tubing is made of stainless steel, duplex stainless steel or nickle alloy. The coiled tubing mostly is welded & redrawn tube or seamless cold drawn tube.

|  |

Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

Payment | T/T, LC or as negotiation | |

Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

Package | Wooden or iron reel or as per customer’s requirement | |

Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

Quality | Test | NDT(Ultrasonic test, Eddy Current test) |

Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test) | ||

Metal Test(Metallographic Analysis, Impact Test-High/low temperature) | ||

Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

An increasing number of projects in the oil service industry require the use of continuous lengths of nickel alloy chemical injection lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex chemical injection lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.