| Availability: | |

|---|---|

| Quantity: | |

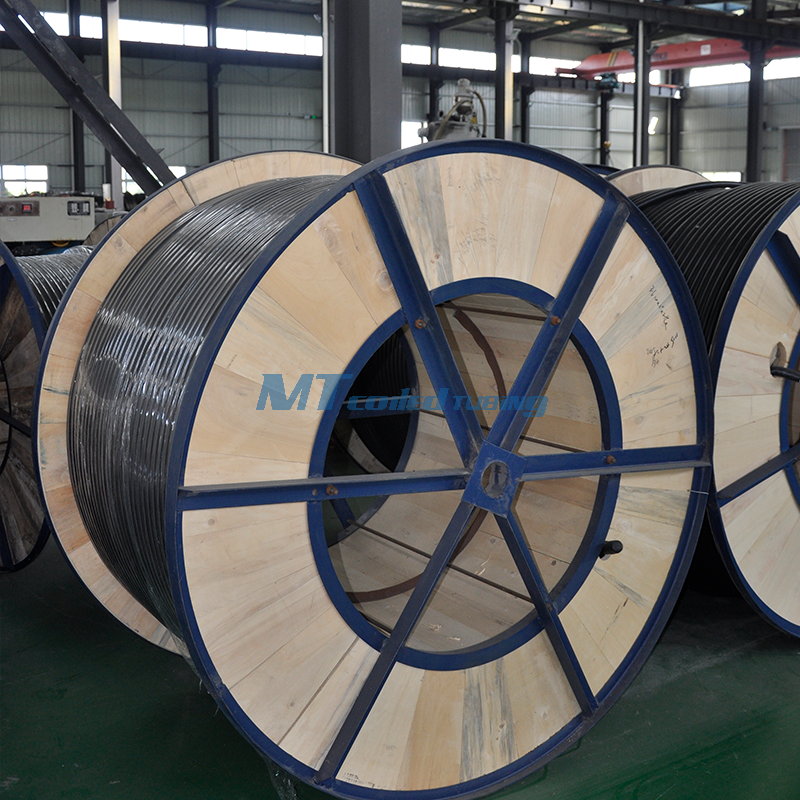

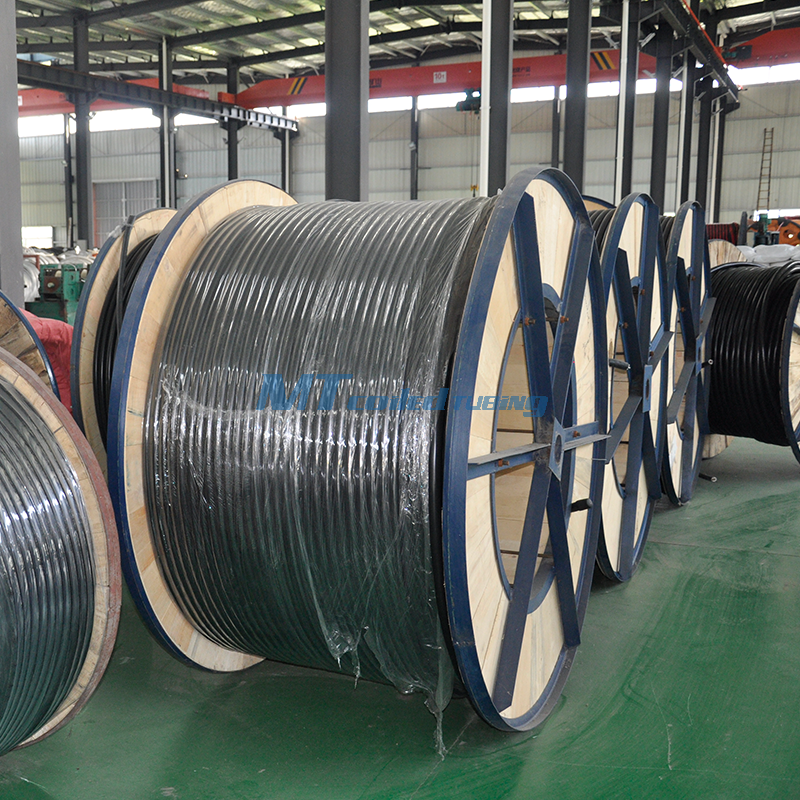

Duplex Steel 2205/2507 ASTM A789 Marine Cable Industry Multi-core Tubing

| Material: TP304/L, TP316/L, S32205, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/N06625 | |

| Outer Diameter: 1/4'', 3/8'',1/2'' | |

| Wall Thickness: 0.035'',0.049'',0.065'' | |

| Length : PER FT | |

| Application : ICV remote control | |

| Pressure Rating : 15000 Psi | |

| Type : HYDRAULIC FLAT PACK | |

| Additional Material Specs : PVDF Encapsulation | Size : 3lines x 1/4" 0.049WT |

| Additional Features : Color coded, Oil filling, Fluid filling | Encapsulation Size : 33 x 11mm |

Multi-core Tubing is A small-diameter tube used to operate downhole completion equipment such as the surface controlled subsurface safety valve (SCSSV), is available in five materials, varying wallthicknesses, and a wide range of working pressure ratings. By manufacturing technique, hydraulic control line has 2 categories, Welded tube and Seamless tube.

Multi-core Tubing also is available as per the customer requirement to provide additional crush and abrasion resistance during installation.

As the well configuration, completion technique and more wells workover come up, hydraulic control line demand has been dramatically increased, more demand comes from offshore Deepwater operation, which requires encapsulation multi-core tubing. On the other hand, new technologies are being introduced to the oilfield, like intelligent completion, this boost up hydraulic control line demand.

|  |

Smoothbore control line used in fibre optic applications;

Test to be done

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| 2205 | ||||||||||

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| 2507 | ||||||||||

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

MTSCO multi-core tubing has been successfully applied to some harsh seabed and downhole conditions. Through continuous research and development, it can meet the strict quality requirements of the oil and gas industry and other industries.

We have obtained various classification society certificates such as BV, DNV, CCS, ABS, LR, etc. In addition, the factory is also equipped with eddy current test, hydraulic test, pressure test, tensile test and other test equipment to ensure the quality of products before delivery.

Duplex Steel 2205/2507 ASTM A789 Marine Cable Industry Multi-core Tubing

| Material: TP304/L, TP316/L, S32205, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/N06625 | |

| Outer Diameter: 1/4'', 3/8'',1/2'' | |

| Wall Thickness: 0.035'',0.049'',0.065'' | |

| Length : PER FT | |

| Application : ICV remote control | |

| Pressure Rating : 15000 Psi | |

| Type : HYDRAULIC FLAT PACK | |

| Additional Material Specs : PVDF Encapsulation | Size : 3lines x 1/4" 0.049WT |

| Additional Features : Color coded, Oil filling, Fluid filling | Encapsulation Size : 33 x 11mm |

Multi-core Tubing is A small-diameter tube used to operate downhole completion equipment such as the surface controlled subsurface safety valve (SCSSV), is available in five materials, varying wallthicknesses, and a wide range of working pressure ratings. By manufacturing technique, hydraulic control line has 2 categories, Welded tube and Seamless tube.

Multi-core Tubing also is available as per the customer requirement to provide additional crush and abrasion resistance during installation.

As the well configuration, completion technique and more wells workover come up, hydraulic control line demand has been dramatically increased, more demand comes from offshore Deepwater operation, which requires encapsulation multi-core tubing. On the other hand, new technologies are being introduced to the oilfield, like intelligent completion, this boost up hydraulic control line demand.

|  |

Smoothbore control line used in fibre optic applications;

Test to be done

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| 2205 | ||||||||||

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| 2507 | ||||||||||

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

MTSCO multi-core tubing has been successfully applied to some harsh seabed and downhole conditions. Through continuous research and development, it can meet the strict quality requirements of the oil and gas industry and other industries.

We have obtained various classification society certificates such as BV, DNV, CCS, ABS, LR, etc. In addition, the factory is also equipped with eddy current test, hydraulic test, pressure test, tensile test and other test equipment to ensure the quality of products before delivery.