| Availability: | |

|---|---|

| Quantity: | |

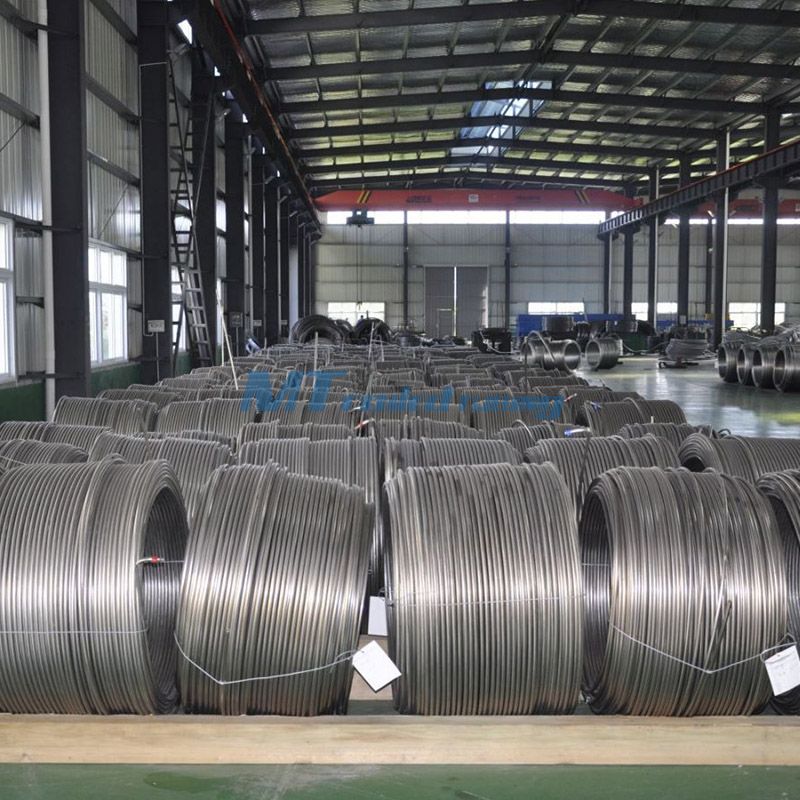

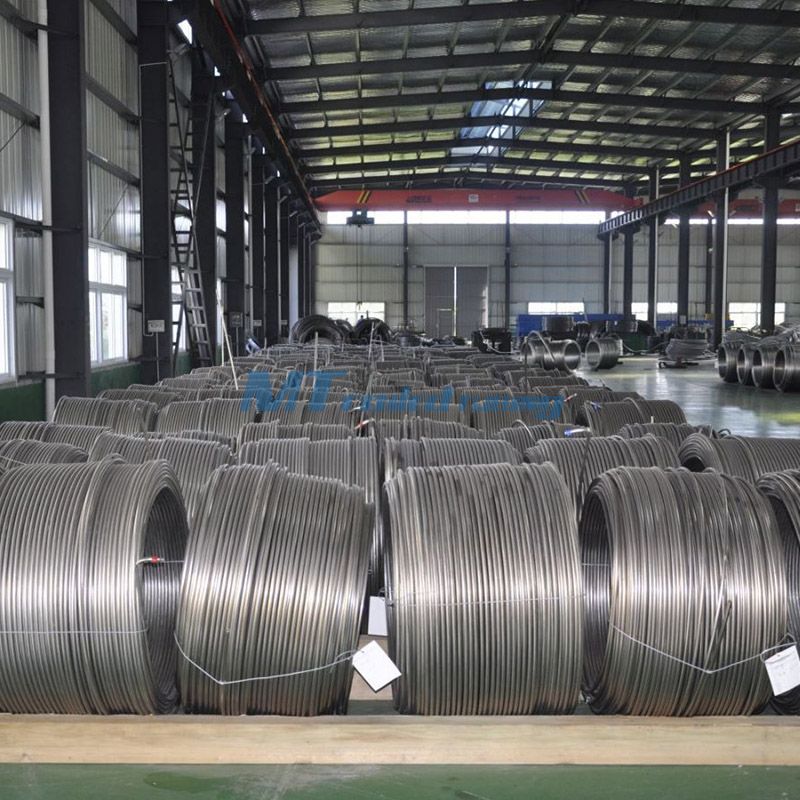

Duplex Steel 2205 Chemical Hydraulic Instrument Tubing with CCS/DNV

Material: S32205, S32507, TP316/L, TP304/L, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 4mm-25mm

Wall Thickness: 0.3mm-2.5mm

Hole count: Single/Multi Core

Length : According to customers' needs, up to 10000m

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

Package: Wooden or iron reel

Advantages Of Coil Tubing

The traditional method of welding long stick tubing end to end or with fittings, it is a very labor intensive procedure., this welding process is very slow and costly, using coil tubing not only takes a fraction of the time, reducing labor costs, it also provides for a much safer and maintenance free installation.

UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

max | max | max | max | max | ||||||

S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

2205 | ||||||||||

S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

2507 | ||||||||||

S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

|  |

An increasing number of projects in the oil service industry require the use of continuous lengths of Hydraulic Instrument Tubing. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex hydraulic instrument tubing. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

Duplex Steel 2205 Chemical Hydraulic Instrument Tubing with CCS/DNV

Material: S32205, S32507, TP316/L, TP304/L, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 4mm-25mm

Wall Thickness: 0.3mm-2.5mm

Hole count: Single/Multi Core

Length : According to customers' needs, up to 10000m

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

Package: Wooden or iron reel

Advantages Of Coil Tubing

The traditional method of welding long stick tubing end to end or with fittings, it is a very labor intensive procedure., this welding process is very slow and costly, using coil tubing not only takes a fraction of the time, reducing labor costs, it also provides for a much safer and maintenance free installation.

UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

max | max | max | max | max | ||||||

S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

2205 | ||||||||||

S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

2507 | ||||||||||

S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

|  |

An increasing number of projects in the oil service industry require the use of continuous lengths of Hydraulic Instrument Tubing. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex hydraulic instrument tubing. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.