| Availability: | |

|---|---|

| Quantity: | |

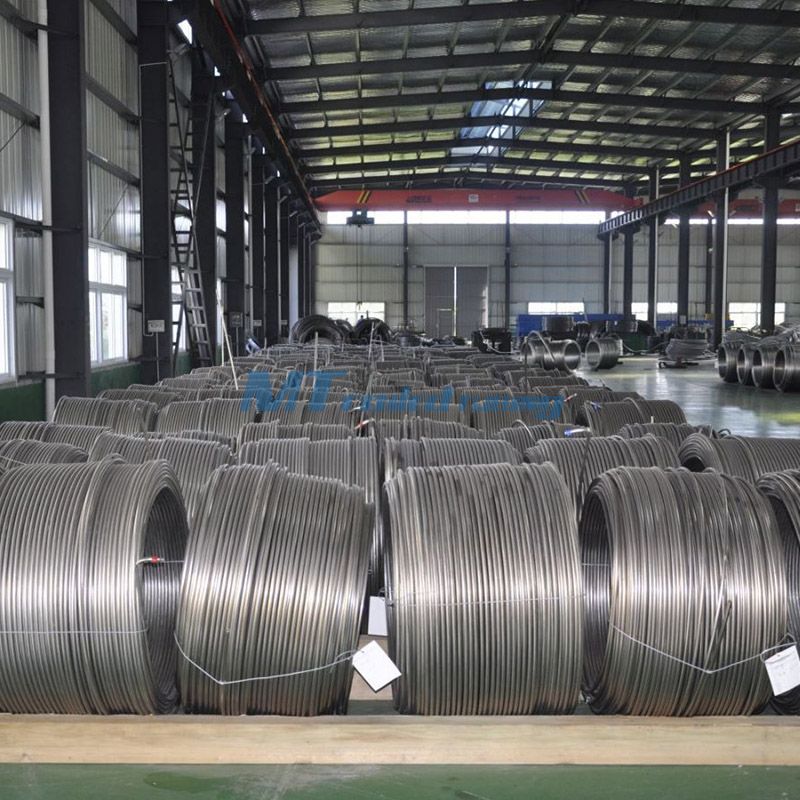

An increasing number of projects in the oil service industry require the use of continuous lengths of nickel alloy control lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex control lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

Grade | Alloy400/ N04400, Alloy825/N08825, Alloy625 /N06625, 2205, 2507, TP316/L, TP304/L, etc |

Type | Welded |

Hole count | Single/Multi Core |

Outer Diameter | 4mm-25mm |

Wall Thickness | 0.3mm-2.5mm |

Length | According to customers’needs, up to 10000m |

Standard | ASTM A269/A213/A789/B704/B163,etc. |

Certificate | ISO/CCS/DNV/BV/ABS, etc. |

Inspection | NDT; Hydrostatic test |

Package | Wooden or iron reel |

|  |

Nickel Alloy 400 Chemical Composition:

% | Ni | Cu | Fe | C | Mn | Si | S |

min | 63 | 28 | |||||

max | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

Nickel Alloy 400 Physical properties

Density | 8.80 g/cm3 |

Melting range | 1300-1350℃ |

Features: Alloy 400 has excellent resistance to corrosion by many reducing media such as sulfuric and hydrochloric acids. It is generally more resistant to corrosion by oxidizing media than higher copper alloys. Alloy 400 resists pitting and stress corrosion cracking in most fresh and industrial waters. It has good resistance in flowing seawater, but under stagnant conditions, pitting and crevice corrosion is induced. Alloy 400 is probably the most resistant to hydrofluoric acid in all concentrations up to the boiling point, of all engineering alloys. Alloy 400 is notable for its toughness, it does not show embrittlement tendency at cryogenic temperatures. It is work hardenable.

Applications: Chemical process equipment, crude oil stills, gasoline and fresh water tanks, marine engineering equipment, valves, pumps and fasteners.

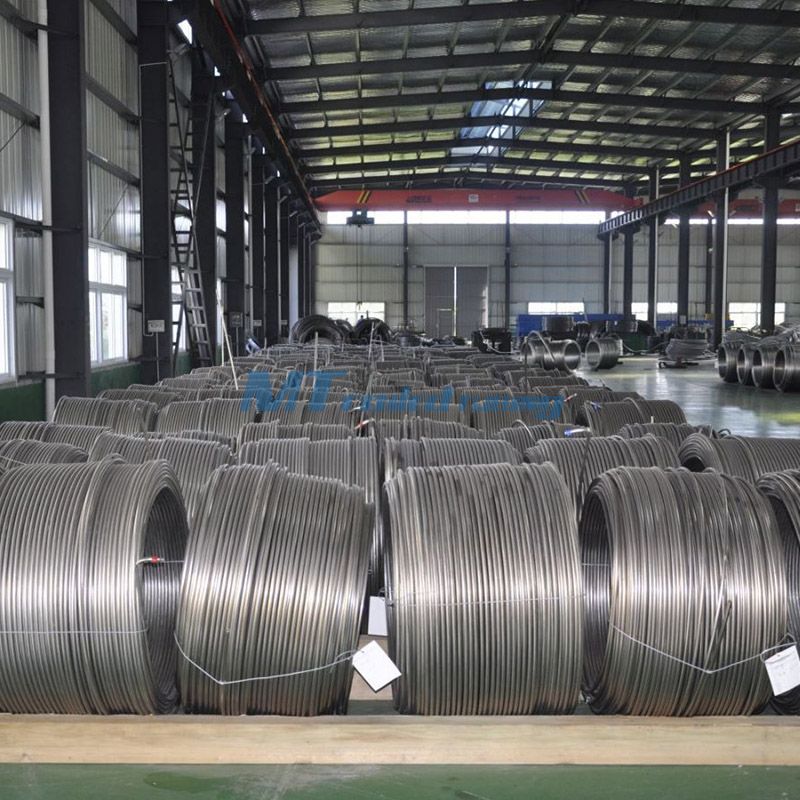

An increasing number of projects in the oil service industry require the use of continuous lengths of nickel alloy control lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products for all of these applications, helping customers reduce operating costs and improve recovery methods.

MTSCO can provide continuous tubing for nickel alloy, stainless steel and duplex control lines. Sizes, lengths, pressure levels, packaging methods, etc. can all be customized to improve your oil recovery methods and reduce operating costs.

Grade | Alloy400/ N04400, Alloy825/N08825, Alloy625 /N06625, 2205, 2507, TP316/L, TP304/L, etc |

Type | Welded |

Hole count | Single/Multi Core |

Outer Diameter | 4mm-25mm |

Wall Thickness | 0.3mm-2.5mm |

Length | According to customers’needs, up to 10000m |

Standard | ASTM A269/A213/A789/B704/B163,etc. |

Certificate | ISO/CCS/DNV/BV/ABS, etc. |

Inspection | NDT; Hydrostatic test |

Package | Wooden or iron reel |

|  |

Nickel Alloy 400 Chemical Composition:

% | Ni | Cu | Fe | C | Mn | Si | S |

min | 63 | 28 | |||||

max | 34 | 2.5 | 0.3 | 2 | 0.5 | 0.024 |

Nickel Alloy 400 Physical properties

Density | 8.80 g/cm3 |

Melting range | 1300-1350℃ |

Features: Alloy 400 has excellent resistance to corrosion by many reducing media such as sulfuric and hydrochloric acids. It is generally more resistant to corrosion by oxidizing media than higher copper alloys. Alloy 400 resists pitting and stress corrosion cracking in most fresh and industrial waters. It has good resistance in flowing seawater, but under stagnant conditions, pitting and crevice corrosion is induced. Alloy 400 is probably the most resistant to hydrofluoric acid in all concentrations up to the boiling point, of all engineering alloys. Alloy 400 is notable for its toughness, it does not show embrittlement tendency at cryogenic temperatures. It is work hardenable.

Applications: Chemical process equipment, crude oil stills, gasoline and fresh water tanks, marine engineering equipment, valves, pumps and fasteners.