| Availability: | |

|---|---|

| Quantity: | |

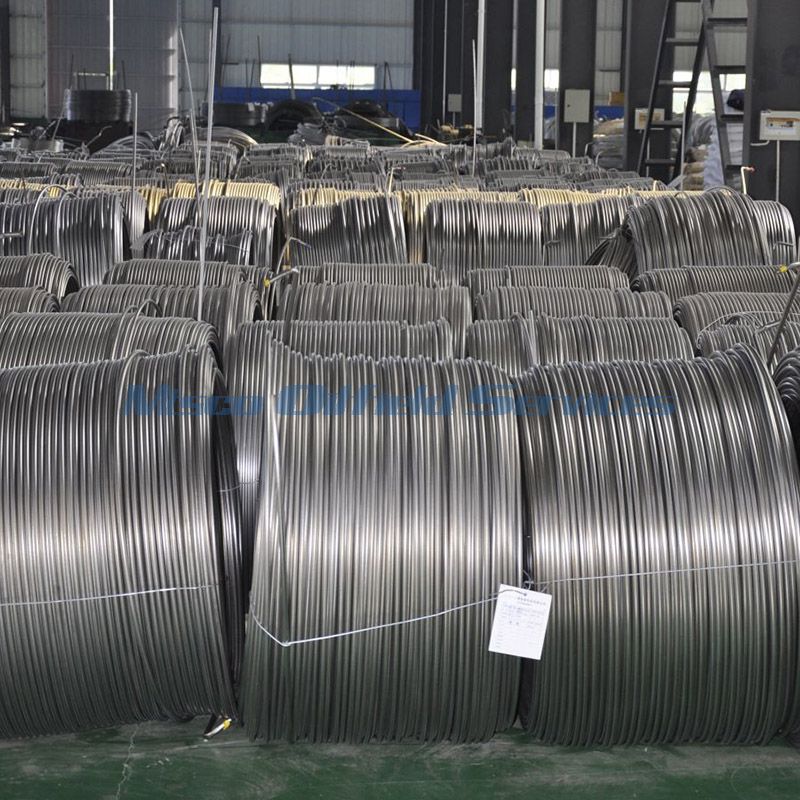

Stainless Steel 316L/316Ti ASTM A269 Welded Capillary Tube for Chemical Injection

| Grade | Alloy 825/N08825, Alloy 625 /N06625, Alloy 400/ N04400, 2205, 2507, TP316/L, TP304/L, etc |

| Type | Welded |

| Hole count | Single/Multi Core |

| Outer diameter | 4mm-88.9mm |

| Wall thickness | 0.3mm-2.5mm |

| Length | According to customers’ needs, up to 33000fts/coil |

| Standard | ASTM A269/A213/A789/B704/B163,etc. |

| Certificate | ISO/CCS/DNV/BV/ABS, etc. |

| Inspection | NDT; Hydrostatic test |

| Package | Wooden or iron reel |

Coiled tubing presents various advantages that revolutionize the conventional approach to oil pipe installation. Traditionally, the labor-intensive process of welding long rods of oil pipe end-to-end or to fittings proved slow and costly. Coiled tubing, however, offers a more efficient and cost-effective alternative, minimizing both time and labor expenses while ensuring a safer and maintenance-free installation.

The benefits of coiled tubing are as follows:

Improved corrosion resistance: Coiled tubing stands out for its superior corrosion resistance, thanks to the properties of stainless steel, duplex, and nickel alloys.

Increased reliability: Utilizing fewer mechanical fittings or welding in the coiled tubing process diminishes the likelihood of defects, such as leaks and other potential long-term failures, thereby enhancing overall reliability.

Reduced installation labor costs: Installing continuous lengths of pipe with coiled tubing proves more time-efficient and reliable compared to connecting multiple shorter lengths of pipe. This not only streamlines the installation process but also contributes to cost savings in labor.

|  |

| Material | C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti |

| TP304/1.4301 | 0.08 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

1 . Our company has been dedicated to producing coiled tubing since 2007, owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , CCS , ABS, DNV,etc , also can be provided according to customers’ requirements .

5 . The tolerance control is strictly accordance to produce standards . Our products are always satisfied with customers . Customers purchased our products created more profits .

6. We have complete after-sale service to deal with the problems in time .

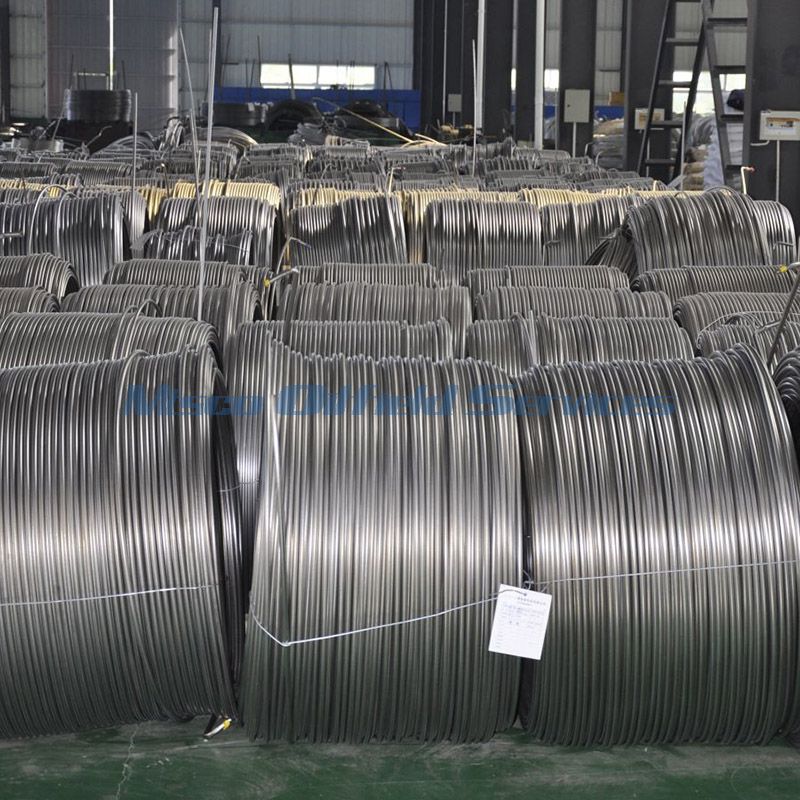

Stainless Steel 316L/316Ti ASTM A269 Welded Capillary Tube for Chemical Injection

| Grade | Alloy 825/N08825, Alloy 625 /N06625, Alloy 400/ N04400, 2205, 2507, TP316/L, TP304/L, etc |

| Type | Welded |

| Hole count | Single/Multi Core |

| Outer diameter | 4mm-88.9mm |

| Wall thickness | 0.3mm-2.5mm |

| Length | According to customers’ needs, up to 33000fts/coil |

| Standard | ASTM A269/A213/A789/B704/B163,etc. |

| Certificate | ISO/CCS/DNV/BV/ABS, etc. |

| Inspection | NDT; Hydrostatic test |

| Package | Wooden or iron reel |

Coiled tubing presents various advantages that revolutionize the conventional approach to oil pipe installation. Traditionally, the labor-intensive process of welding long rods of oil pipe end-to-end or to fittings proved slow and costly. Coiled tubing, however, offers a more efficient and cost-effective alternative, minimizing both time and labor expenses while ensuring a safer and maintenance-free installation.

The benefits of coiled tubing are as follows:

Improved corrosion resistance: Coiled tubing stands out for its superior corrosion resistance, thanks to the properties of stainless steel, duplex, and nickel alloys.

Increased reliability: Utilizing fewer mechanical fittings or welding in the coiled tubing process diminishes the likelihood of defects, such as leaks and other potential long-term failures, thereby enhancing overall reliability.

Reduced installation labor costs: Installing continuous lengths of pipe with coiled tubing proves more time-efficient and reliable compared to connecting multiple shorter lengths of pipe. This not only streamlines the installation process but also contributes to cost savings in labor.

|  |

| Material | C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti |

| TP304/1.4301 | 0.08 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

1 . Our company has been dedicated to producing coiled tubing since 2007, owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , CCS , ABS, DNV,etc , also can be provided according to customers’ requirements .

5 . The tolerance control is strictly accordance to produce standards . Our products are always satisfied with customers . Customers purchased our products created more profits .

6. We have complete after-sale service to deal with the problems in time .