| Availability: | |

|---|---|

| Quantity: | |

Material: TP316/L, TP304/L, S32205, S32750, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 1/4“, 3/8”,1/2“

Wall Thickness: 0.035”,0.049“,0.065”

Hole count: Single/Multi Core

Length : According to customers’ needs, up to 10000m

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

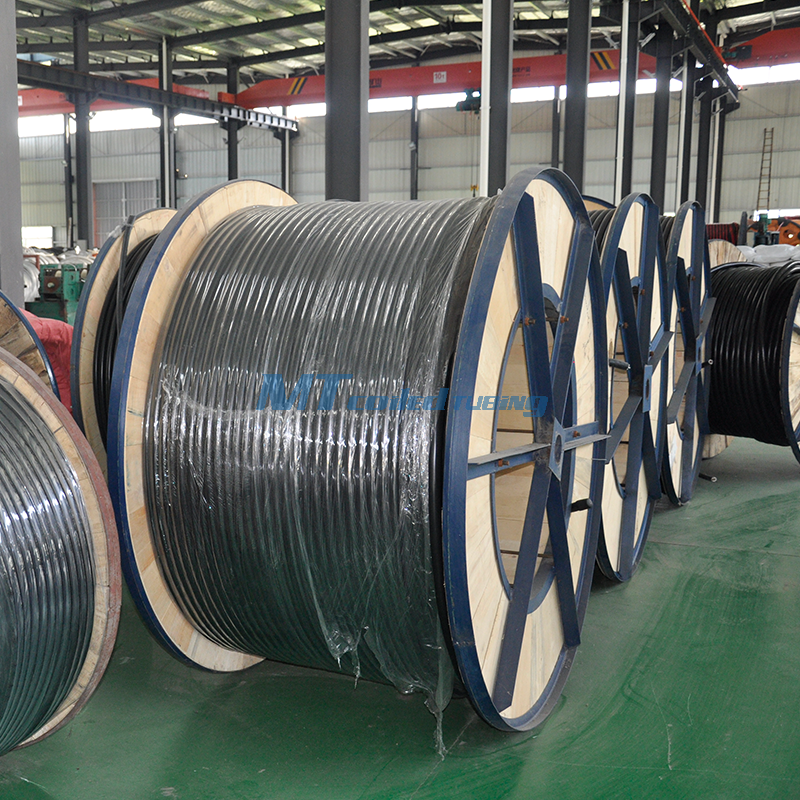

Package: Wooden or iron reel

|  |

Plastic Packaging Materials | Abbreviation | Temperature℃ |

Ethylene Tetrafluoroethylene | ETFE | -60℃~150℃ |

Fluoronated Ethylene Propylene | FEP | -110℃~200℃ |

High Density Polyethylene | HDPE | -60℃~100℃ |

Perfluoroalkoxy | PFA | -80℃~260℃ |

Modified Polypropylene | PP | 30℃~150℃ |

Polyvinylidene Fluoride | PVDF | -30℃~150℃ |

Thermoplastic Vulcanizating | TPV | -30℃~150℃ |

Nylon11 | PA11 | -30℃~150℃ |

Where the control line used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

Material | ASTM A269 Chemical Composition % Max | ||||||||||

C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^. | ^ |

TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

|   |

More Details About MTSCO Control Line :

1 . Our company has been dedicated to producing coiled tubing since 2007, owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , CCS , ABS, DNV,etc , also can be provided according to customers’ requirements .

5 . The tolerance control is strictly accordance to produce standards . Our products are always satisfied with customers . Customers purchased our products created more profits .

6. We have complete after-sale service to deal with the problems in time .

Material: TP316/L, TP304/L, S32205, S32750, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 1/4“, 3/8”,1/2“

Wall Thickness: 0.035”,0.049“,0.065”

Hole count: Single/Multi Core

Length : According to customers’ needs, up to 10000m

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

Package: Wooden or iron reel

|  |

Plastic Packaging Materials | Abbreviation | Temperature℃ |

Ethylene Tetrafluoroethylene | ETFE | -60℃~150℃ |

Fluoronated Ethylene Propylene | FEP | -110℃~200℃ |

High Density Polyethylene | HDPE | -60℃~100℃ |

Perfluoroalkoxy | PFA | -80℃~260℃ |

Modified Polypropylene | PP | 30℃~150℃ |

Polyvinylidene Fluoride | PVDF | -30℃~150℃ |

Thermoplastic Vulcanizating | TPV | -30℃~150℃ |

Nylon11 | PA11 | -30℃~150℃ |

Where the control line used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

Material | ASTM A269 Chemical Composition % Max | ||||||||||

C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^. | ^ |

TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

|   |

More Details About MTSCO Control Line :

1 . Our company has been dedicated to producing coiled tubing since 2007, owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , CCS , ABS, DNV,etc , also can be provided according to customers’ requirements .

5 . The tolerance control is strictly accordance to produce standards . Our products are always satisfied with customers . Customers purchased our products created more profits .

6. We have complete after-sale service to deal with the problems in time .