| Availability: | |

|---|---|

| Quantity: | |

Material: TP304/L, TP316/L, S32205, S32750, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 1/4“, 3/8”,1/2“

Wall Thickness: 0.035”,0.049“,0.065”

Hole count: Single/Multi Core

Length : According to customers' needs, up to 10000m

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

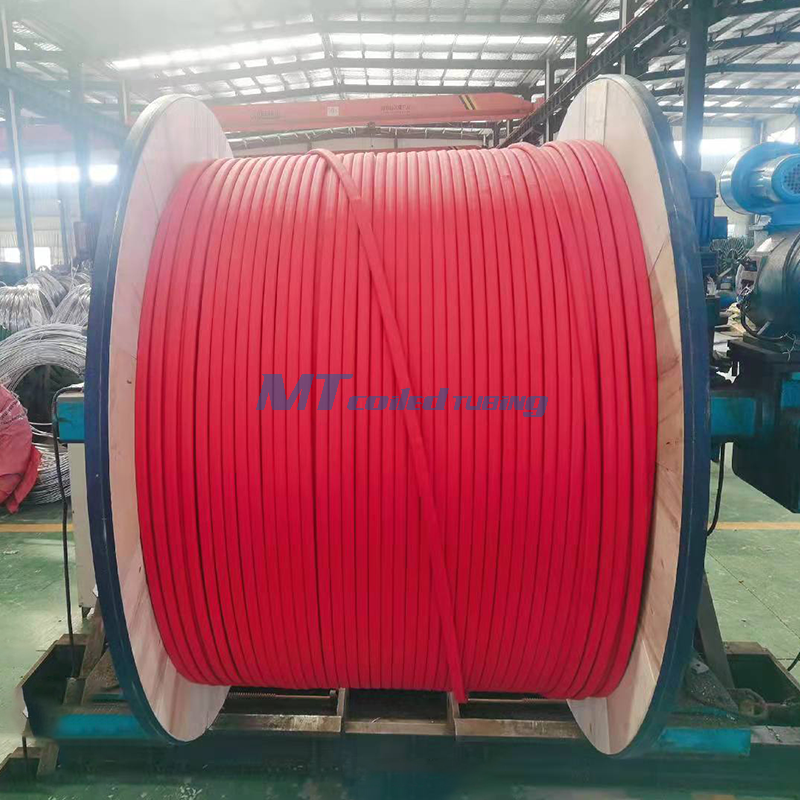

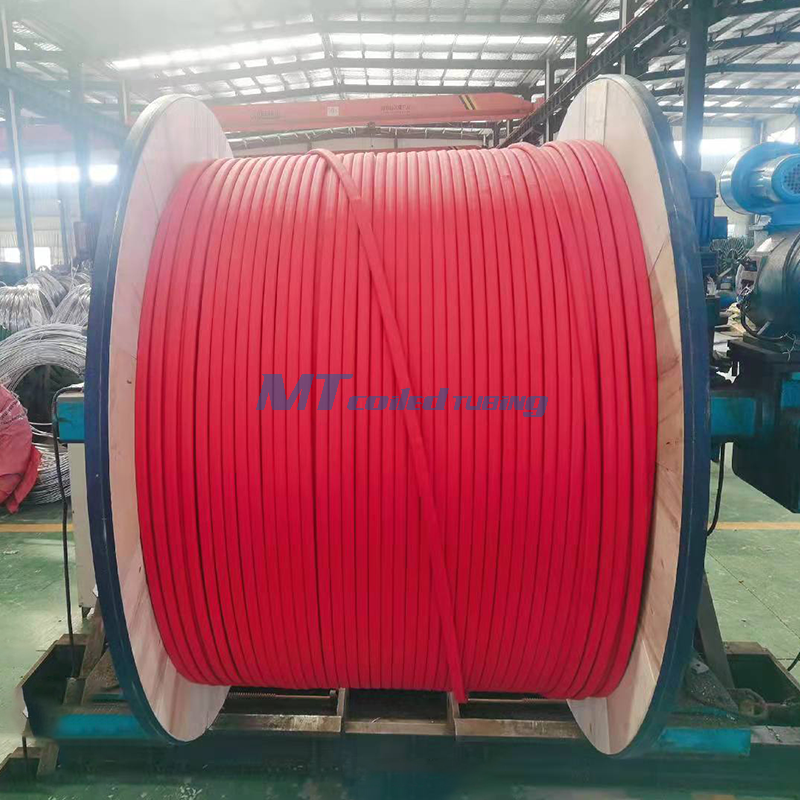

Package: Wooden or iron reel

Where the control line used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

|  |

Material | ASTM A269 Chemical Composition % Max | ||||||||||

C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^. | ^ |

TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

What is a control line seal?

For a variety of reasons, many wells have a hydraulic control line that runs down the casing or tubing and is used to control valves or sleeves or other equipment.

Sometimes these control lines leak and can no longer be used, and sometimes they are just not needed anymore.

These control lines can extend downhole for hundreds or even thousands of meters.

Faulty control lines can be the source of accidental leaks. In the abandonment phase, control lines can be the source of pressure migration or piping.

More Details About MTSCO Control Line :

1 . Our company has been dedicated to producing coiled tubing since 2007, owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , CCS , ABS, DNV,etc , also can be provided according to customers’ requirements .

5 . The tolerance control is strictly accordance to produce standards . Our products are always satisfied with customers . Customers purchased our products created more profits .

6. We have complete after-sale service to deal with the problems in time .

Material: TP304/L, TP316/L, S32205, S32750, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Outer Diameter: 1/4“, 3/8”,1/2“

Wall Thickness: 0.035”,0.049“,0.065”

Hole count: Single/Multi Core

Length : According to customers' needs, up to 10000m

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

Package: Wooden or iron reel

Where the control line used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

|  |

Material | ASTM A269 Chemical Composition % Max | ||||||||||

C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^. | ^ |

TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ | ||

What is a control line seal?

For a variety of reasons, many wells have a hydraulic control line that runs down the casing or tubing and is used to control valves or sleeves or other equipment.

Sometimes these control lines leak and can no longer be used, and sometimes they are just not needed anymore.

These control lines can extend downhole for hundreds or even thousands of meters.

Faulty control lines can be the source of accidental leaks. In the abandonment phase, control lines can be the source of pressure migration or piping.

More Details About MTSCO Control Line :

1 . Our company has been dedicated to producing coiled tubing since 2007, owning complete producing technology and abundant managing experience .

2 . The raw material such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Yongxing etc .

3 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on .

4 . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , CCS , ABS, DNV,etc , also can be provided according to customers’ requirements .

5 . The tolerance control is strictly accordance to produce standards . Our products are always satisfied with customers . Customers purchased our products created more profits .

6. We have complete after-sale service to deal with the problems in time .